The Data Driven Future

Beef Marbling

See the difference. Taste the difference.

Customers can see it - we are here to provide it.

Marble Score: 2

Marble Score: 5

Marble Score: 8

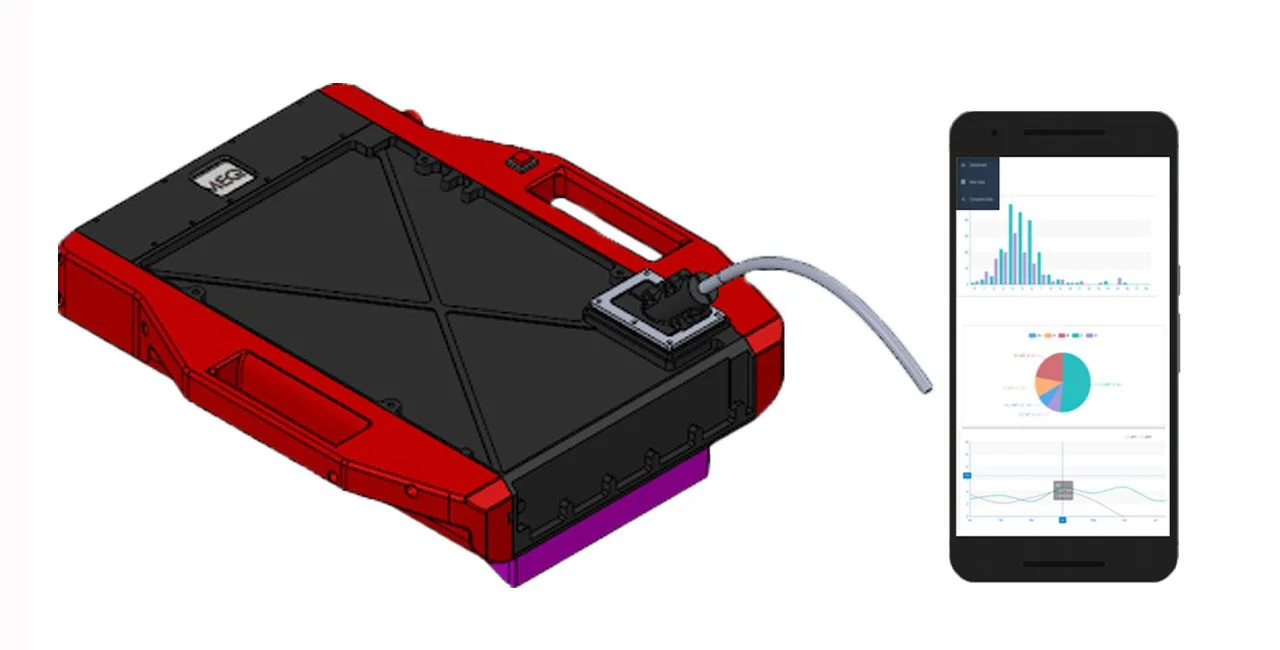

The MEQ Probe

Our patented technology is the world’s first accredited hot carcase measure in beef.

Grade into the chillers – optimising chillers and saving energy

Early grading enables 20x the time to optimise how the carcase will be sold into the supply chain, optimising carcase value and enabling more products to be allocated into branded ranges

Less time in chillers means easier boning of the carcase that helps OHS of employees and carcase yield extraction

Objective data means correct allocation into brands and better information back to breeders

How MEQ Probe Delivers the Data-Driven Future

PROCESSORS

Process to brand specification and supply chain need

Optimise chiller use and save energy, improving sustainability of processing

Determine eating quality to support and reinforce brand promises

Hot carcase grading enables optimisation of carcase value

Environmental Sustainability

MEQ Probe creates a positive impact on sustainability by reducing GHG emissions for processors in the following ways:

Optimising chiller space in processors – processing plants have warehouses of chillers

Reduces energy usage through a shorter ageing time

Reduces energy usage through a shorter chilling time of carcases

Probe makes hot gassing of carcases redundant, another way it reduces energy usage

Camera App

The MEQ Camera provides cold carcase yield and eating quality measures. Measures such as Rib Eye Area, Marbling, IMF%, and much more. The camera can be used on its own or as a compliment to the MEQ Probe.

MEQ Live

Real time data solution for feedlots and producers

Use yield and marbling values to understand more about the animal performance

Know if feed conversion is driving high value (Rib Eye Area, Mb) or low value (Rib Fat) performance

The processor can capture yield and marbling pre-chillers

Feed data back to breeding and genetics for superior performance

Predict the carcase value at induction or even earlier

How MEQ Live Delivers the Data-Driven Future

FEEDLOTS

Optimise days on feed to have minimal impact on environment and profitability

Manage to a product specification rather than days on feed

Know the performance of the animal while managing it, not just at processing

Accelerate genetics and breeding performance

Know the relationship between feed vs genetics

Know the value of the livestock assets in real time, given quality and yield measures

Environmental Sustainability

MEQ Live creates a positive impact on sustainability helping feedlots in the following ways:

Reduce feed whilst still achieving the same animal specifications, thereby reducing the volume of grain required

Identify genetically suited cattle for the feedlot environment to improve average health and eating quality and reduce waste in the system

Managing animals only for the time needed rather than an arbitrary program – reducing enteric methane emissions

Shift feed regime from generic days on feed to days required to achieve a product specification